Strainers are placed in-line with process piping to remove large solid contaminants from the flow. Strainers can be cleaned and reused. Strainers can be supplied as either an assembly or an element. Strainer assemblies come equipped with a housing, cover or case, and a strainer element. A strainer element is a simple mesh or perforated metal element that may be used as replacement or a handheld strainer. Strainers can be used in a wide variety of applications, including but not limited to: general purpose, chemical, coolant, food processing, laboratory, industrial, high temperature, high viscosity, hydraulic fluid, medical or pharmaceutical, oil or fuel, refrigerant and water. We are a team of skilled professionals , every member of our company is committed to produce premium quality products . We having a third party inspection to ensure the premium quality of manufactured goods.

Materials of Construction

Strainers can have a connection that is welded, flanged, threaded, clamped or brazed or soldered. Materials of construction include bronze, cast iron, nickel alloy, carbon or alloy steel, stainless steel, titanium, polyvinyl chloride (PVC), polyethylene (PE), or polypropylene (PP, PPL). Fiberglass strainers and rugged strainers made of reinforced plastics and composite materials are also commonly available.

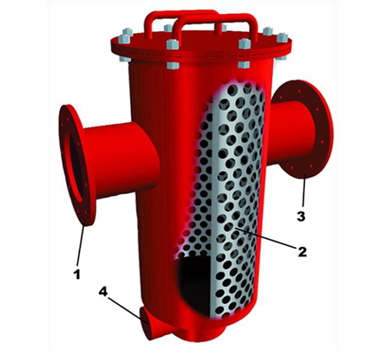

1 ) Simplex / Basket Strainers :- A simplex basket strainer is used where the line can be shut down for short periods to clean or change baskets. It becomes an integral part of the pipeline and all flow passes through it. These filters are provided with single cartridge / basket , so they are called simplex strainers.

Size Range :- | |

| Screwed | ( ¼” to 3” ) |

| Flange | ( ½” to 12” in casted material) (2” to 40” in fabricated material) |

2 ) Duplex Strainers:- Duplex strainers remove damage causing particulate matter from the process media, and never have to be shut down for cleaning. The line can run continuously. When one strainer basket becomes full, flow is switched to the other. The first basket is removed, cleaned and is ready for use again. Some basket filters are 'temporary' and are intended for start-up use only. In-line strainers are positioned with the basket parallel to the line of fluid flow. It can be manufactured in casting / fabrication as per requirement .Duplex Strainer can also be available with steam jacketing for fluid like (L.D.O. / H.F.O. Bitumen etc.)

Size Range :- | |

| In casting | ( ½” to 4”) |

| In fabrication | (1” to 6” with 3 way ball valve design ) ( 8” to 40” with disc & spigot changeover ) |

3 ) T Type Strainers:- T type strainers are particularly adapted where basket replacement needs to be made quickly. It is synonymous with its name .It is available in screw and flanged construction . Available in forged , cast and fabricated construction . It is used for Inline application.

Size Range :- | |

| ( 1” to 2” in casted material) ( 3” to 12 “ in fabricated material) |

|

4 ) Y Type Strainers :- Y-strainers are devices for mechanically removing solids from flowing liquids or gases by means of a perforated or wire mesh straining element. They are used in pipelines to protect equipment such as pumps, meters, control valves, steam traps, and regulators. Simplest kind of strainer , can be used as pipe fitting .Basket area to pipeline C.S.A ratio of 2.5:1 in casted construction , it can be given as per requirement in fabricated construction.

Size Range :- | |

| Screwed Connection | ( ½” to 3”) |

| Flange Connection | ( 1” to 12” in casted material) ( 3” to 20 “ in fabricated material) |

5 ) Conical Strainers:- These are also called temporary strainers used as strainer for testing of the line . Conical line strainers are used to protect fluid and gas handling equipment by removing debris during the start-up of a system. They are easily installed between large flange faces without modifying the surrounding pipe work and they are easily removed. They are "temporary" strainers and are intended for start-up use only. These are available in SS 304 / SS 316 / M.S. / Brass construction . These are easily mounted between the flanges and are available in different flange sizes like I.S. series , D.I.N. Standard , J.I.S. Standard , A.S.A and other National and International standards.

6 ) Suction Strainers:- Suction filters suitable for installations in the storage tanks below liquid on pump’s suction inlet pipe .It protect hydraulic pumps and control systems from solid contaminants. They should be used as immersion suction filters on pump inlet lines. These units have various application possibilities: as in-tank filters mounted directly to the reservoir, in the intake lines of hydraulic pumps to afford a degree of protection from contaminants to the pump and other components in the hydraulic system .These are available in S.S. 304 / S.S. 316 / M.S. / Mass construction.

7 ) Self Cleaning Our Self-Cleaning improves your product quality by removing oversize contamination from 10 micron or above. Without the need for filter bags or cartridges and with significant reductions in wasted product over traditional filters, our range of industrial filters are both cost-effective and environmentally friendly. For water services it can be used for coarse filtration with M.S. / G.I.

The range of self-cleaning filters is designed for ease of operation and maintenance. They are simple to disassemble and clean without tools, allowing for fast and efficient product line changeovers, therefore increasing productivity. The units fit neatly into existing production lines, providing considerable filtration capacity without requiring excessive space.