We put forward a broad range of Filters It is ideally suitable for protection against harmful particles and any type of impurities and undesirable substance . Our offered filter is manufactured in adherence with the set industry standards using advanced technology and optimum quality raw material. In tune with international quality standard, we provide the entire range in various sizes and specifications as per the requirement of our clients. Our quality controllers perform a series of test on various parameters, in order to ensure the quality of this filter. Apart from this, clients can avail the entire range from us at industry leading rates.

We are Manufacturing of all types of Industrial Air Filters , Liquid Filters , Hydraulic Filter, Gas Filter, Filter Fabric, Filter Paper, Filter Pad.

Industrial filters are given below:-

1. Type :- Transparent and Opaque

2. MOC :- SS 304 / 316 L MS Powder Coated Aluminium , Polycarbonate , Cast Iron , Cast Steel etc.

MOC – Pleated SS 304 / 316 L Mesh , Polypropylene , PP weaving , Sintered Bronze , Spun, Glass Fibre , Special Coating PTFE Filters

Sizes / Dimension

10” , 20” , 30” , 40” and as per your requirement and as per drawing

1. Easy installation

2. High functionality with low cost

3. Requires no maintenance

4. Compact design

5. Longer functional life

Filter Elements and Housing develop for Indian and imported, machines and equipments .

These are used to separate and reclaim lubricants in the air , gas stream of air compressor in general and rotary compressor in particular .

It is a pressure precoat filter incorporating special stainless-steel alloy elements having provision of self-cleaning system. The coiled stainless-steel wire forms a foundation for the deposited filter aid bed . It has high filtration efficiency from 5 microns down to 0.5 micron . This can be designed as per clients requirements.

Applications :- Purifying rolling mills oil at aluminium products (foils etc. ) works , clarifying sugar juice at sugar factory , public water supply , polishing sugar syrup for mineral water manufacturer , soft drink factory , pharmaceuticals , precious metal solutions , perfumes , waxes , oils and many other products where a crystal clear filtration is required .

Type

a) 1-5000 micron

b) Nominal and Absolute

Filters & Spares for heavy earthmoving machinery including industrial & hydraulic earthmoving machinery and construction equipments such as excavators , loaders / unloaders , dumpers , cranes dozers , mixers , grabs , trailers , road rollers , generators forklifts etc. for different makes such as JCB , Caterpillar , Komatsu , Terex , BEML , Pocklain , Volvo , Samsung , Hitachi , Haulpak , Kirloskar , Cummins , TIL , Godrej , Voltas etc.

We have developed various filters & spares for these , we can also develop new items as per your specification.

| Bag Type | Snap Ring , Pocket Filter , Ring Type , Collar Type |

| Fabric Material | Non-Woven Polyster , Polypropylene , Nylon, PTFE , Teflon Coated Polypropylene , Nomex, Glass Fibre |

| Usage | Air Filter, Dust Filter, Liquid Filter |

We fabricate high quality dust collector convectional filter bags that are made from superior quality raw material such as base fiber. These dust collector filter bags are precisely fabricated under the strict quality control inspections right from the stage of procurement of raw material to the finished product. The dust collector filter bags are stitched according to clients’ requirement with the state -of-the-art stitching machines. These conventional dust filter bags are widely used in various industries including cement, steel, incinerators, boilers, power stations, salt processing, ceramic and many others.

Benefits: -

1) Bag Filters Custom stitched in house on imported juki machines to suit industry needs.

2) Our bag filters meet the most stringent test for stitching workmanship w.r.t bag dimension & quality of snap / band collar with fitments.

3) Filtration solution to solve problems such as blinding of filter bags, emissions, temperature, moisture and hydrolysis, high differential pressure and inadequate air flow by proper selection of non-woven media.

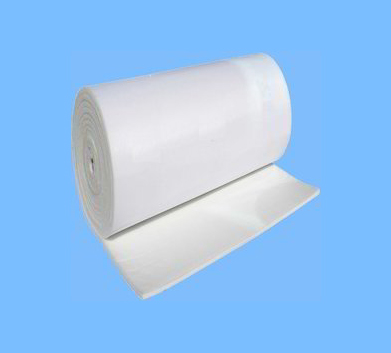

We are paramount in providing a wide range of Filter Media to the valuable patrons including Freudenberg reputed brand name of Filter Media . Our products are manufactured by making use of the optimum quality raw material, which is sourced from the most trusted vendors of the market. These products are used for air-oil separation in compressor applications, tooth paste powder , dust collector , Food industry , seawage & waste water , storm water , gas, Air Conditioning Filter etc. In addition, these are also used in layers for coalescing application.

Features:

Uses of PTFE Coated fabric

Advance Global Industries is the distinguished name in the field of manufacturing, supplying & exporting premium range of PTFE Coated Fabric. Constructed with woven fiberglass cloth specifically coated with PTFE resin, the standard fabric has the exemplifying design.PTFE ( Polytetrafluoro Ethylene) is the technical name of the material.

The superior coating has the needed strength along with the dimensional stability of the fiberglass. Moreover, it offers easy release and has heat resistance of PTFE. It features comparatively heavier coating of PTFE.

The advanced PTFE coated fabric is available in a wide variety of designs, sizes and models. It has been carved keeping in mind the specific usability in many industries. Besides, it is customized as well to meet each specification.

We have a dedicated team of most experienced professionals who make sure the products are tested at every stage in order to have flawless quality. The standard fabric is used in many applications such as, composite mold release, polymer processing, food dehydration, release sheets, separation materials etc.

In addition to being slippery, the material also brings a number of other features to the table, offering high temperature resistance, little reaction to most chemicals, and reduced stress cracking and corrosion. These features make PTFE perfect for numerous applications, including:

Advantage